EVA: Polyethylene-co-vinyl acetate

- Short Name

- EVA

- Name

- Polyethylene-co-vinyl acetate

- Group

- CTP - Commodity Thermoplastics

- General Properties

- Chemical Formula

- (C2H4)n(C4H6O2)m

- Structural Formula

-

Properties

- Glass Transition Temperature

- -40 to +20 °C

- Melting Temperature

- 30 to 110 °C

- Melting Enthalpy

- 10 to 100 J/g

- Decomposition Temperature

- 345 to 360 / 470 to 480 °C

- Young's Modulus

- 7 to 120 MPa

- Coefficient of Linear Thermal Expansion

- 160 to 200 *10¯6/K

- Specific Heat Capacity

- 2.3 J/(g*K)

- Thermal Conductivity

- 0.35 W/(m*K)

- Density

- 0.92 to 0.95 g/cm³

- Morphology

- Semi-crystalline thermoplastic

- General properties

- High flexibility and toughness, good aging stability, high weather resistance, high gloss.

- Processing

- Injection moulding

- Applications

- Textile industry, hot melt adhesive, photovoltaic (embedding agent), agriculture and horticulture (films), cling films, shrink wrappings, shoe soles (VA-amount > 30 %)

Internet Links

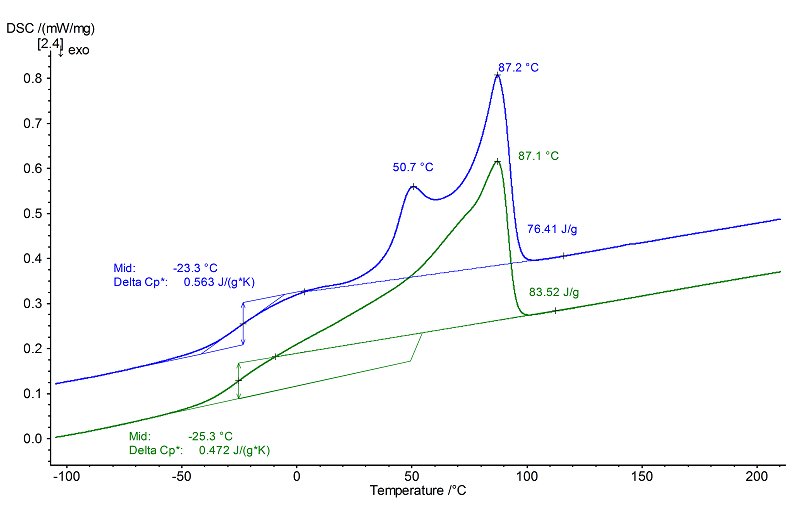

NETZSCH Measurements

- Instrument

- DSC 204 F1 Phoenix®

- Sample Mass

- 10.65 mg

- Isothermal Phase

- 8 min

- Heating/Colling Rates

- 10 K/min

- Crucible

- Al, piercec

- Atmosphere

- N2 (50 ml/min)

Evaluation

In the above graphics, only the 1st heating (blue) was evaluated since the effects in the 2nd heating − after controlled cooling – are no longer resolved.

In the 1st heating (blue curve), the glass transition occurs at -23°C (midpoint, with a change in specific heat of 0.56 J/(g·K)). It is followed by two overlapping, endothermal melting effects at 51°C and 87°C (peak temperatures). The entire heat of fusion of the combined peaks amounts to approx. 75 J/g.

In the 1st heating (blue curve), the glass transition occurs at -23°C (midpoint, with a change in specific heat of 0.56 J/(g·K)). It is followed by two overlapping, endothermal melting effects at 51°C and 87°C (peak temperatures). The entire heat of fusion of the combined peaks amounts to approx. 75 J/g.