PVC-P: Polyvinylchloride (with plasticizer)

- Short Name

- PVC-P

- Name

- Polyvinylchloride (with plasticizer)

- Group

- CTP - Commodity Thermoplastics

- General Properties

- Chemical Formula

- Structural Formula

-

Properties

- Glass Transition Temperature

- -50 to 80 °C

- Melting Temperature

- - °C

- Melting Enthalpy

- - J/g

- Decomposition Temperature

- 290 to 315 / 460 to 475 °C

- Young's Modulus

- 25 to 1600 MPa

- Coefficient of Linear Thermal Expansion

- 60 to 120 *10¯6/K

- Specific Heat Capacity

- 0.8 to 0.9 J/(g*K)

- Thermal Conductivity

- 0.13 to 0.20 W/(m*K)

- Density

- 1.16 to 1.35 g/cm³

- Morphology

- Amorphous thermoplastic

- General properties

- Good chemical resistance, good electrical insulation, low humidity absorption.

- Processing

- Extrusion (hoses, cables), calendering.

- Applications

- Building industry, toys, furniture industry, electrical engineering, packaging, agriculture.

Internet Links

NETZSCH Measurements

- Instrument

- DSC 204 F1 Phoenix®

- Sample Mass

- 12.98 mg

- Isothermal Phase

- 7 min

- Heating/Colling Rates

- 10 K/min

- Crucible

- Al, pierced

- Atmosphere

- N2 (40 ml/min)

Evaluation

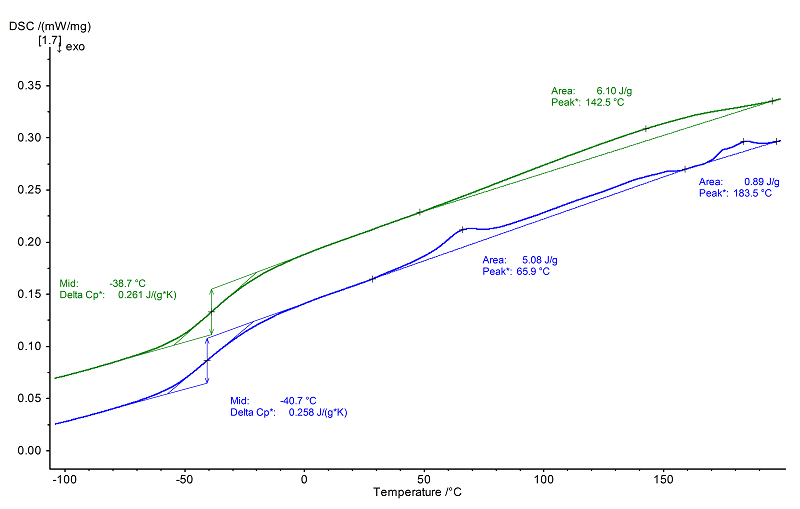

Due to the plasticizer additive, the glass transition temperature Tg was at -41°C in the 1st heating (blue) and -39°C in the 2nd heating (green). Evaluation of the step heights (Δcp) yielded a value of approx. 0.26 J/(g·K) in both heatings.

With the help of the 1st heating (blue), the degree of gelation of the PVC can be determined*. This requires calculation of two peak areas, i.e., of Ha between T1 and process temperature T2 (representing the amount already gelled) as well as of Hb

between T2 and T3 (representing the amount not yet gelled).

The degree of gelation (G) in % is calculated from the ratio of Ha and the total enthalpy (Ha + Hb) multiplied by 100. In the present case, this evaluation leads to a result of 85.1%. Since the end temperature of the 1st heating was at 200°C, only one peak was visible in the 2nd heating (green) since the entire PVC was already gelled.

With the help of the 1st heating (blue), the degree of gelation of the PVC can be determined*. This requires calculation of two peak areas, i.e., of Ha between T1 and process temperature T2 (representing the amount already gelled) as well as of Hb

between T2 and T3 (representing the amount not yet gelled).

The degree of gelation (G) in % is calculated from the ratio of Ha and the total enthalpy (Ha + Hb) multiplied by 100. In the present case, this evaluation leads to a result of 85.1%. Since the end temperature of the 1st heating was at 200°C, only one peak was visible in the 2nd heating (green) since the entire PVC was already gelled.