PVAL: Polyvinylalcohol

- Short Name

- PVAL

- Name

- Polyvinylalcohol

- Group

- CTP - Commodity Thermoplastics

- General Properties

- Chemical Formula

- Structural Formula

-

Properties

- Glass Transition Temperature

- 70 to 100 °C

- Melting Temperature

- 220 to 260 °C

- Melting Enthalpy

- 156 J/g

- Decomposition Temperature

- 260 to 320 / 420 to 450 °C

- Young's Modulus

- - MPa

- Coefficient of Linear Thermal Expansion

- - *10¯6/K

- Specific Heat Capacity

- 1.55 J/(g*K)

- Thermal Conductivity

- - W/(m*K)

- Density

- 1.21 g/cm³

- Morphology

- Semi-crystalline thermoplastic

- General properties

- Good solubility in water, good resistance against organic solvents, good film formation properties, high bonding strength

- Processing

- Extrusion

- Applications

- Water-soluble films, adhesives, toys (e.g. component of modelling clay), textiles, textile fibres, medical technology, pharmacy (e.g. tablet coatings).

Internet Links

NETZSCH Measurements

- Instrument

- DSC 204 F1 Phoenix®

- Sample Mass

- 10.26 mg

- Isothermal Phase

- 5 min

- Heating/Colling Rates

- 10 K/min

- Crucible

- Al, pierced

- Atmosphere

- N2 (50 ml/min)

Evaluation

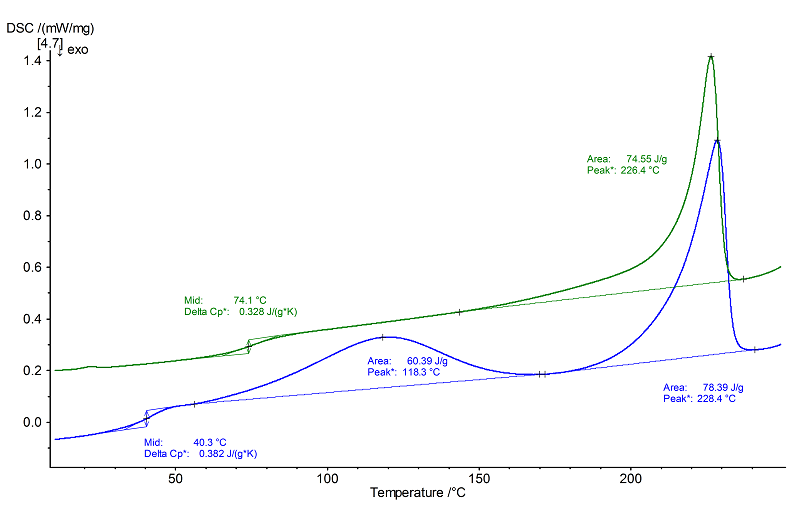

Water has plasticizing properties. For this reason, the glass transition is considerably lower in the 1st heating (blue) than in the 2nd heating (green) by 34 K. Directly related to this is the broad endothermal effect between approx. 60°C and 170°C

(1st heating). It can be attributed to the evaporation of humidity. By using aluminum crucibles with pierced lids, water was eliminated from the sample during the 1st heating.

Above 150°C and 170°C, PVAL exhibited melting transition with peak temperatures of 229°C (1st heating, blue) and 226°C (2nd heating, green). The corresponding melting enthalpies were approx. 78 J/g (1st heating) and 75 J/g (2nd heating), respectively.

(1st heating). It can be attributed to the evaporation of humidity. By using aluminum crucibles with pierced lids, water was eliminated from the sample during the 1st heating.

Above 150°C and 170°C, PVAL exhibited melting transition with peak temperatures of 229°C (1st heating, blue) and 226°C (2nd heating, green). The corresponding melting enthalpies were approx. 78 J/g (1st heating) and 75 J/g (2nd heating), respectively.