PLA: Polylactide

- Short Name

- PLA

- Name

- Polylactide

- Group

- CTP - Commodity Thermoplastics

- General Properties

- Chemical Formula

- Structural Formula

-

Properties

- Glass Transition Temperature

- 45 to 65 °C

- Melting Temperature

- 150 to 160 °C

- Melting Enthalpy

- 93 to 140 J/g

- Decomposition Temperature

- 350 to 375 °C

- Young's Modulus

- 350 to 2800 MPa

- Coefficient of Linear Thermal Expansion

- - *10¯6/K

- Specific Heat Capacity

- - J/(g*K)

- Thermal Conductivity

- - W/(m*K)

- Density

- 1.21 to 1.43 g/cm³

- Morphology

- Semi-crystalline thermoplastic

- General properties

- Good mechanical properties, low humidity absorption, high UV-resistance, low flammability.

- Processing

- Extrusion, injection molding, melt spinning

- Applications

- Fibres (yarns, textiles), packaging, agriculture and horticulture, medical engineering (e.g. suture material).

Internet Links

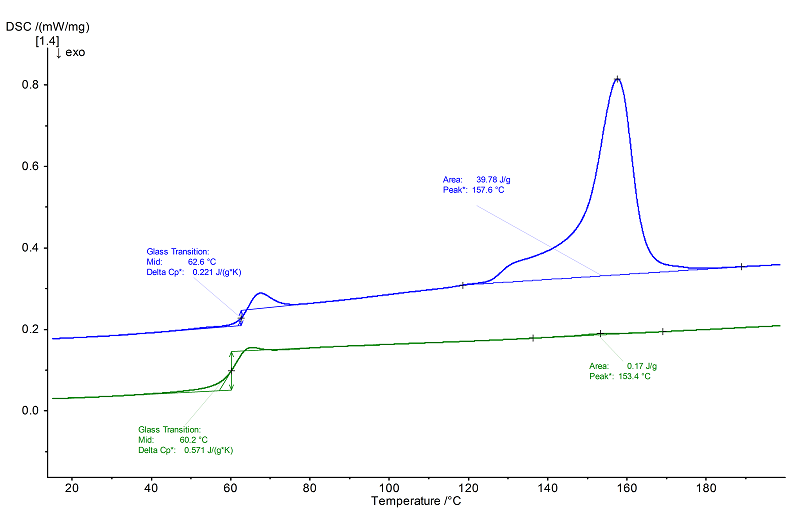

NETZSCH Measurements

- Instrument

- DSC 204 F1 Phoenix®

- Sample Mass

- 14.32 mg

- Isothermal Phase

- 5 min

- Heating/Colling Rates

- 10 K/min

- Crucible

- Al, pierced

- Atmosphere

- N2 (50 ml/min)

Evaluation

Polylactic acid showed a glass transition at 63°C in the 1st heating (midpoint, blue) which was overlapped by a relaxation peak as well as a melting peak between approx. 130°C and 180°C (peak temperature 158°C with a preceding shoulder). The following controlled cooling at 10 K/min was too quick for the material to crystallize. Therefore, only a very small melting effect at 153°C and a larger glass transition step (with a higher Δcp of 0.57 J/(g·K) compared to 0.22 J/(g·K) in the 1st heating) occurred in the 2nd heating due to the higher percentage of amorphous material.