PA46: Polyamide 46

- Short Name

- PA46

- Name

- Polyamide 46

- Group

- ETP - Engineering Thermoplastics

- General Properties

- Chemical Formula

- Structural Formula

-

Properties

- Glass Transition Temperature

- 70 to 94 °C

- Melting Temperature

- 290 to 295 °C

- Melting Enthalpy

- - J/g

- Decomposition Temperature

- 440 to 450 °C

- Young's Modulus

- 3300 MPa

- Coefficient of Linear Thermal Expansion

- 70 to 80 *10¯6/K

- Specific Heat Capacity

- 2.1 J/(g*K)

- Thermal Conductivity

- 0.3 W/(m*K)

- Density

- 1.18 to 1.21 g/cm³

- Morphology

- Semi-crystalline thermoplastic

- General properties

- High heat resistance. High stiffness and stability at higher temperatures. Good creep resistance. Good chemical resistance

- Processing

- Extrusion

- Applications

- Mechanical and apparatus engineering. Automotive engineering. Electro and electrical engineering. Fibers, zip ties

Internet Links

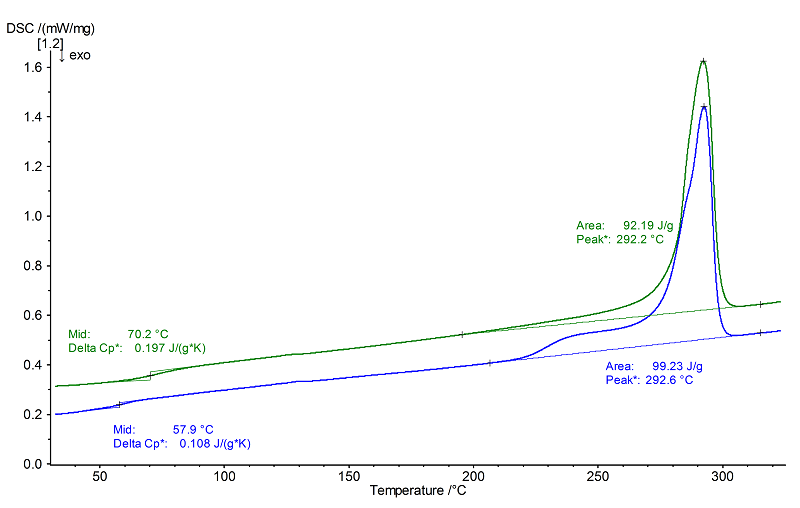

NETZSCH Measurements

- Instrument

- DSC 204 F1 Phoenix®

- Sample Mass

- 10.68 mg

- Isothermal Phase

- 5 min

- Heating/Colling Rates

- 10 K/min

- Crucible

- Al, pierced

- Atmosphere

- N2 (50 ml/min)

Evaluation

In this example, an endothermal melting effect was observed with a peak temperature of 292°C (2nd heating, green) and an enthalpy of 91 J/g. The midpoint temperature of 58°C of the glass transition in the 1st heating (blue) increased to 74°C in the 2nd heating (green) as a result of water evaporation (small peak at 129°C with an enthalpy of 0.6 J/g) during the 1st heating.

The shoulder at around 240°C prior to the main melting peak in the 1st heating is due to the thermomechanical history of the sample since it was absent in the 2nd heating.

The shoulder at around 240°C prior to the main melting peak in the 1st heating is due to the thermomechanical history of the sample since it was absent in the 2nd heating.