PA610: Polyamide 610

- Short Name

- PA610

- Name

- Polyamide 610

- Group

- ETP - Engineering Thermoplastics

- General Properties

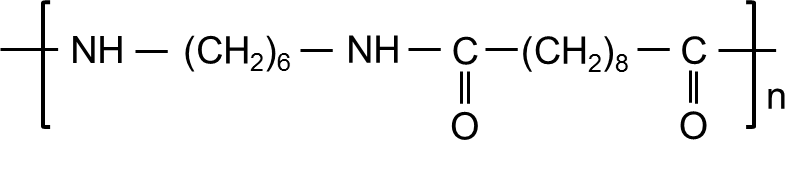

- Chemical Formula

- Structural Formula

-

Properties

- Glass Transition Temperature

- 40 to 70 °C

- Melting Temperature

- 210 to 230 °C

- Melting Enthalpy

- 117 to 227 J/g

- Decomposition Temperature

- 450 to 470 °C

- Young's Modulus

- 2200 MPa

- Coefficient of Linear Thermal Expansion

- 70 to 90 *10¯6/K

- Specific Heat Capacity

- 1.6 J/(g*K)

- Thermal Conductivity

- 0.2 W/(m*K)

- Density

- 1.07 to 1.09 g/cm³

- Morphology

- Semi-crystalline thermoplastic

- General properties

- Very high mechanical strength. Good UV and chemical resistance. Good heat resistance. Low water absorption compared to short-chained standard polyamides

- Processing

- Injection molding, extrusion, film blowing

- Applications

- Housings, transmission components. Electronic components. Pipes, plug-in connectors or container in cooling circuits

Internet Links

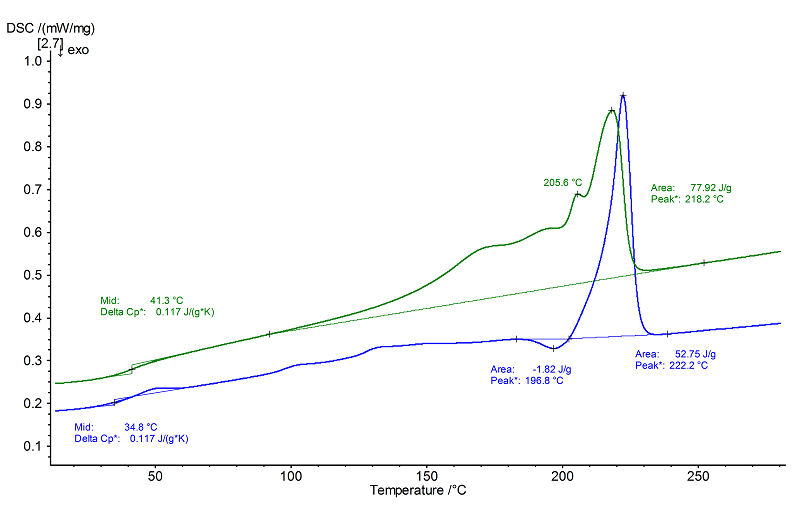

NETZSCH Measurements

- Instrument

- DSC 204 F1 Phoenix®

- Sample Mass

- 10.50 mg

- Isothermal Phase

- 5 min

- Heating/Colling Rates

- 10 K/min

- Crucible

- Al, pierced

- Atmosphere

- N2 (50 ml/min)

Evaluation

The present sample shows a glass transition at 41°C in the 2nd heating (green), which is relatively low for polyamide 6.10, as well as a broad melting range with a total melting enthalpy of 71 J/g. The structure of the melting peak in the 2nd heating

indicates the presence of different crystalline phases. The temperature of the endothermal main peak at 218°C is in the typical range for PA6.10.

Immediately before melting, an exothermal post-crystallization occurred in the 1st heating (blue). The shallow signals between 90°C and approx. 140°C (also 1st heating) could be caused by the release of stress in the material and/or evaporation of water.

indicates the presence of different crystalline phases. The temperature of the endothermal main peak at 218°C is in the typical range for PA6.10.

Immediately before melting, an exothermal post-crystallization occurred in the 1st heating (blue). The shallow signals between 90°C and approx. 140°C (also 1st heating) could be caused by the release of stress in the material and/or evaporation of water.