PA612: Polyamide 612

- Short Name

- PA612

- Name

- Polyamide 612

- Group

- ETP - Engineering Thermoplastics

- General Properties

- Chemical Formula

- Structural Formula

-

Properties

- Glass Transition Temperature

- 40 to 65 °C

- Melting Temperature

- 210 to 220 °C

- Melting Enthalpy

- - J/g

- Decomposition Temperature

- 450 to 465 °C

- Young's Modulus

- 2100 to 2250 MPa

- Coefficient of Linear Thermal Expansion

- 120 to 130 *10¯6/K

- Specific Heat Capacity

- 1.91 J/(g*K)

- Thermal Conductivity

- - W/(m*K)

- Density

- 1.06 g/cm³

- Morphology

- Semi-crystalline thermoplastic

- General properties

- High toughness. Very good resistance to fats, oils, fuels. Very good stress cracking resistance. Low coefficient of sliding friction. High abrasion resistance

- Processing

- Injection molding

- Applications

- Vehicle construction. Household items, e.g., toothbrushes. Plastic-rubber composites, e.g., for housing covers with seals

Internet Links

NETZSCH Measurements

- Instrument

- DSC 204 F1 Phoenix®

- Sample Mass

- 8.66 mg

- Isothermal Phase

- 8 min

- Heating/Colling Rates

- 10 K/min

- Crucible

- Al, pierced

- Atmosphere

- N2 (50 ml/min)

Evaluation

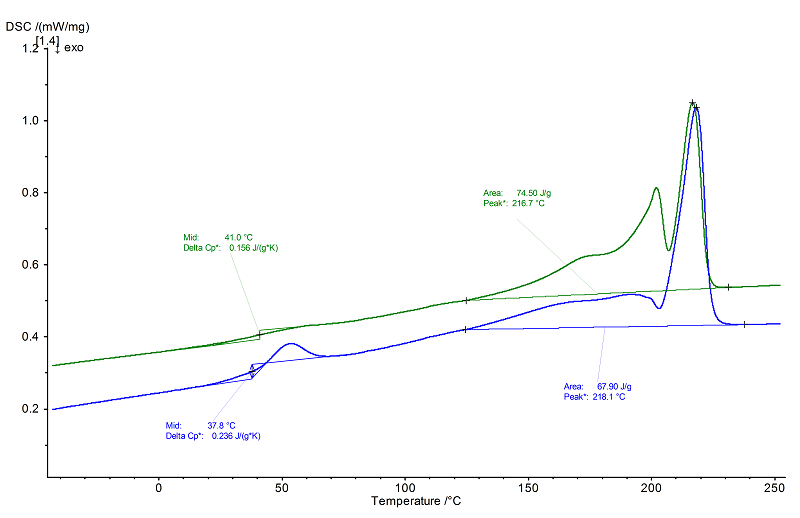

Shown in the 2nd heating (green) of this example is a broad, strongly structured endothermal melting transition with a distinctive pre-peak at 202°C and an additional shoulder at 173°C (peak temperatures). The temperature of the main effect (also peak temperature) occurred at 217°C. The total melting enthalpy was approx. 75 J/g.

The glass transition in the 2nd heating had a midpoint temperature of 40°C, at the lower end of the glass transition temperature for these materials. In the 1st heating (blue), the Tg midpoint was approximately 2 K lower and overlapped by a large

relaxation peak.

The glass transition in the 2nd heating had a midpoint temperature of 40°C, at the lower end of the glass transition temperature for these materials. In the 1st heating (blue), the Tg midpoint was approximately 2 K lower and overlapped by a large

relaxation peak.