PA66: Polyamide 66

- Short Name

- PA66

- Name

- Polyamide 66

- Group

- ETP - Engineering Thermoplastics

- General Properties

- Chemical Formula

- Structural Formula

-

Properties

- Glass Transition Temperature

- 65 to 90 °C

- Melting Temperature

- 225 to 265 °C

- Melting Enthalpy

- 185 J/g

- Decomposition Temperature

- 430 to 473 °C

- Young's Modulus

- 3000 MPa

- Coefficient of Linear Thermal Expansion

- 35 to 45 *10¯6/K

- Specific Heat Capacity

- 1.67 to 1.70 J/(g*K)

- Thermal Conductivity

- 0.24 to 0.33 W/(m*K)

- Density

- 1.13 to 1.16 g/cm³

- Morphology

- Semi-crystalline thermoplastic

- General properties

- Good mechanical strength. High impact strength. Good damping behavior. Good abrasion resistance

- Processing

- Injection molding

- Applications

- Mechanical, automotive and apparatus engineering, e.g., for plain gearings, gear wheels, sliding plates

Internet Links

NETZSCH Measurements

- Instrument

- DSC 204 F1 Phoenix®

- Sample Mass

- 10.15 mg

- Isothermal Phase

- 5 min

- Heating/Colling Rates

- 10 K/min

- Crucible

- Al, pierced

- Atmosphere

- N2 (50 ml/min)

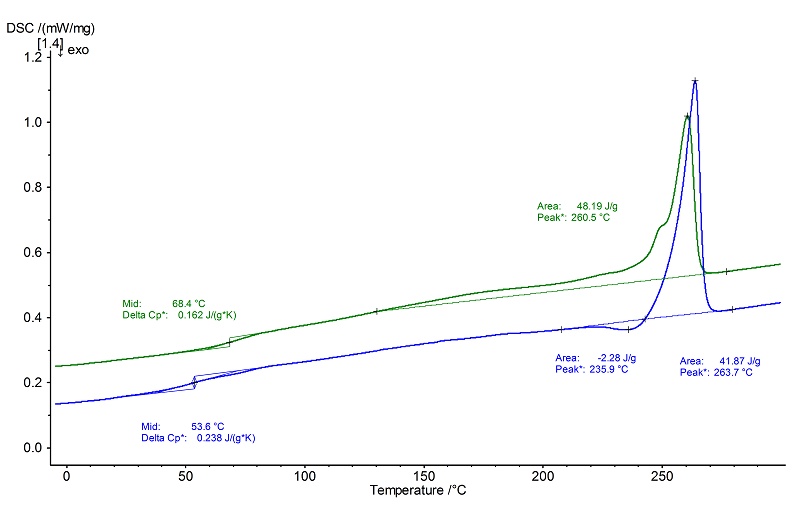

Evaluation

As a semi-crystalline thermoplastic, PA6.6 showed a glass transition at 68°C (midpoint) in the 2nd heating (green) and an endothermal melting range from approx. 200°C to 270°C. As is often the case for PA6.6, a second melting transition at 250°C can be observed as a pre-peak (or shoulder) prior to the actual main melting effect with a peak temperature of 261°C. In the 1st heating (blue), post-crystallization (exothermal effect at 237°C) occurred prior to the melting peak.

The corresponding glass transition temperature in the 1st heating at 54°C (midpoint) is lower than the Tg at 68°C in the 2nd heating due to the presence of a small amount of water, as evidenced by the shallow evaporation peak between 100°C and 200°C (blue curve).

The corresponding glass transition temperature in the 1st heating at 54°C (midpoint) is lower than the Tg at 68°C in the 2nd heating due to the presence of a small amount of water, as evidenced by the shallow evaporation peak between 100°C and 200°C (blue curve).