PC: Polycarbonate

- Short Name

- PC

- Name

- Polycarbonate

- Group

- ETP - Engineering Thermoplastics

- General Properties

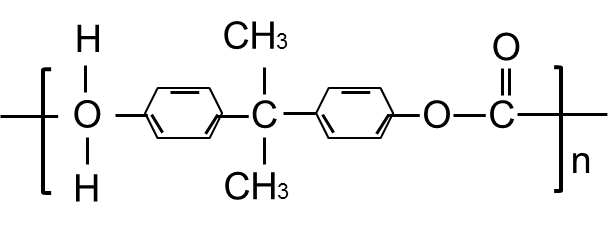

- Chemical Formula

- Structural Formula

-

Properties

- Glass Transition Temperature

- 140 to 150 °C

- Melting Temperature

- - °C

- Melting Enthalpy

- - J/g

- Decomposition Temperature

- 480 to 535 °C

- Young's Modulus

- 2200 to 2400 MPa

- Coefficient of Linear Thermal Expansion

- 75 to 80 *10¯6/K

- Specific Heat Capacity

- 1.17 to 1.50 J/(g*K)

- Thermal Conductivity

- 0.19 to 0.21 W/(m*K)

- Density

- 1.20 to 1.24 g/cm³

- Morphology

- Amorphous thermoplastic

- General properties

- Medium to high stability and stiffness. Very good impact strength. Weather and radiation resistant. High transparency. Very good electrial insulating properties

- Processing

- Injection molding, extrusion, deep drawing

- Applications

- Electronic components. Building sector. Optical storage media, like CD, DVD, Blue-Ray Disc Automobile, plane and safety components. Medical applications. Cellular phones. Products of daily life like, e.g., food containers

Internet Links

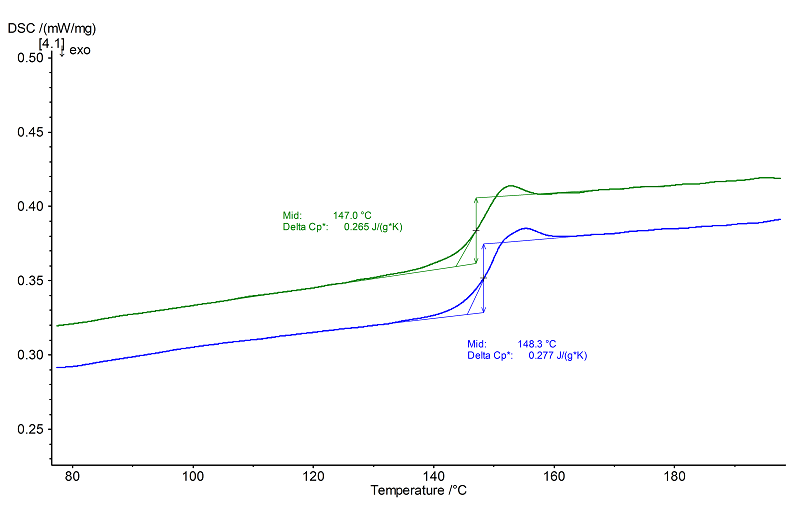

NETZSCH Measurements

- Instrument

- DSC 204 F1 Phoenix®

- Sample Mass

- 12.84 mg

- Isothermal Phase

- 3 min/5 min

- Heating/Colling Rates

- 10 K/min

- Crucible

- Al, pierced

- Atmosphere

- N2 (50 ml/min)

Evaluation

Polycarbonates are generally amorphous. For this reason, the DSC curves (in both the 1st and 2nd heating) show only a glass transition effect.

The corresponding glass transition temperatures (midpoints) are very close to each other in both heatings at 147°C (2nd heating, green) and 148°C (1st heating, blue); the step heights (Δcp) are also similar. Both glass transition were overlapped by relaxation effects.

The corresponding glass transition temperatures (midpoints) are very close to each other in both heatings at 147°C (2nd heating, green) and 148°C (1st heating, blue); the step heights (Δcp) are also similar. Both glass transition were overlapped by relaxation effects.