PSU: Polysulfone

- Short Name

- PSU

- Name

- Polysulfone

- Group

- HTRTP - High-Temperature Resistant Thermoplastics

- General Properties

- Chemical Formula

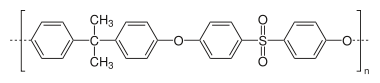

- Structural Formula

-

Properties

- Glass Transition Temperature

- 185 to 190 °C

- Melting Temperature

- - °C

- Melting Enthalpy

- - J/g

- Decomposition Temperature

- 530 to 540 °C

- Young's Modulus

- 2500 to 2700 MPa

- Coefficient of Linear Thermal Expansion

- 50 to 60 *10¯6/K

- Specific Heat Capacity

- 1.37 J/(g*K)

- Thermal Conductivity

- 0.15 W/(m*K)

- Density

- 1.24 to 1.25 g/cm³

- Morphology

- Amorphous polymer

- General properties

- High stability and stiffness. Good toughness. Good chemical resistance. Low water absorption. Very good electrical insulation properties

- Processing

- Injection molding, extrusion for the production of thin films

- Applications

- Electrical engineering (e.g., condensators). Medical engineering. Food technology. Aerospace (helmets). Chemical and laboratory equipment

Internet Links

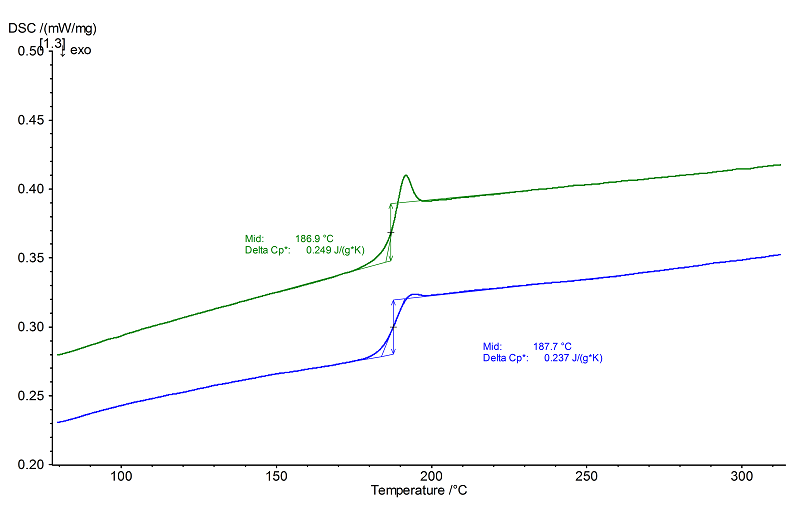

NETZSCH Measurements

- Instrument

- DSC 204 F1 Phoenix®

- Sample Mass

- 12.52 mg

- Isothermal Phase

- 3 min/3 min/5 min

- Heating/Colling Rates

- 10 K/min

- Crucible

- Al, pierced

- Atmosphere

- N2 (40 ml/min)

Evaluation

Since PSU is entirely amorphous, the DSC curves above show only one glass transition with a glass transition midpoint temperature at 187°C in the 2nd heating (green) and 188°C in the 1st heating (blue). The glass transition in the 2nd heating is overlapped by a larger relaxation peak than in the 1st heating. This indicates an increase in short-range order during the controlled cooling at 10 K/min than was originally present in the material.

The heights of the glass transition steps of 0.24 J/(g.K) (1st heating) and 0.25 J/(g.K) (2nd heating) are nearly identical.

The heights of the glass transition steps of 0.24 J/(g.K) (1st heating) and 0.25 J/(g.K) (2nd heating) are nearly identical.