PTFE: Polytetrafluoroethylene

- Short Name

- PTFE

- Name

- Polytetrafluoroethylene

- Group

- HTRTP - High-Temperature Resistant Thermoplastics

- General Properties

- Chemical Formula

- Structural Formula

-

Properties

- Glass Transition Temperature

- 120 to 130 °C

- Melting Temperature

- 325 to 335 °C

- Melting Enthalpy

- 82 J/g

- Decomposition Temperature

- 575 to 590 °C

- Young's Modulus

- 400 to 750 MPa

- Coefficient of Linear Thermal Expansion

- 100 to 150 *10¯6/K

- Specific Heat Capacity

- 1.0 J/(g*K)

- Thermal Conductivity

- 0.23 to 0.25 W/(m*K)

- Density

- 2.13 to 2.23 g/cm³

- Morphology

- Semi-crystalline thermoplastic

- General properties

- Good thermal and oxidative stability. High toughness. Very good chemical resistance. Good electrical insulation. Low friction coefficient. High UV resistance

- Processing

- Special techniques for extrusion, compression/sintering for molding, films, components

- Applications

- Chemical plant construction. Food and pharma technology. Medical engineering. Nonstick coating. Sealing technology. High-frequency technology

Internet Links

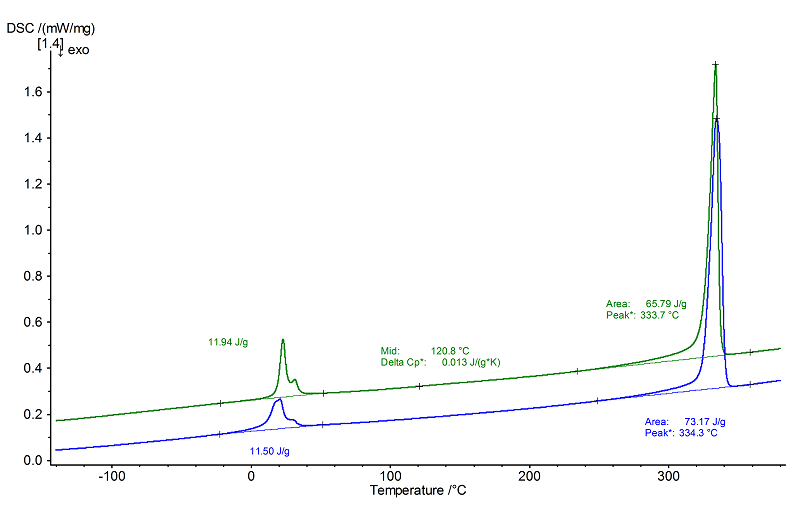

NETZSCH Measurements

- Instrument

- DSC 204 F1 Phoenix®

- Sample Mass

- 12.80 mg

- Isothermal Phase

- 20 min

- Heating/Colling Rates

- 10 K/min

- Crucible

- Al, pierced

- Atmosphere

- N2 (40 ml/min)

Evaluation

The DSC curve of the PTFE sample exhibits two overlapping peaks around 20°C. The peaks were sharper in the 2nd heating (green) than they were in the 1st heating (blue) with peak temperatures of 23°C and 32°C. A very weak glass transition at approx. 130°C was detected in the 2nd heating. The melting transitions peaked at 334°C in both heatings.

The melting enthalpy with 65 J/g in the 2nd heating (green) is approx. 11% below the melting enthalpy in the 1st heating. This indicates a lower crystallinity in the 2nd heating and is consistent with the somewhat clearer glass transition step, which indicates an increase in amorphous content.

The melting enthalpy with 65 J/g in the 2nd heating (green) is approx. 11% below the melting enthalpy in the 1st heating. This indicates a lower crystallinity in the 2nd heating and is consistent with the somewhat clearer glass transition step, which indicates an increase in amorphous content.