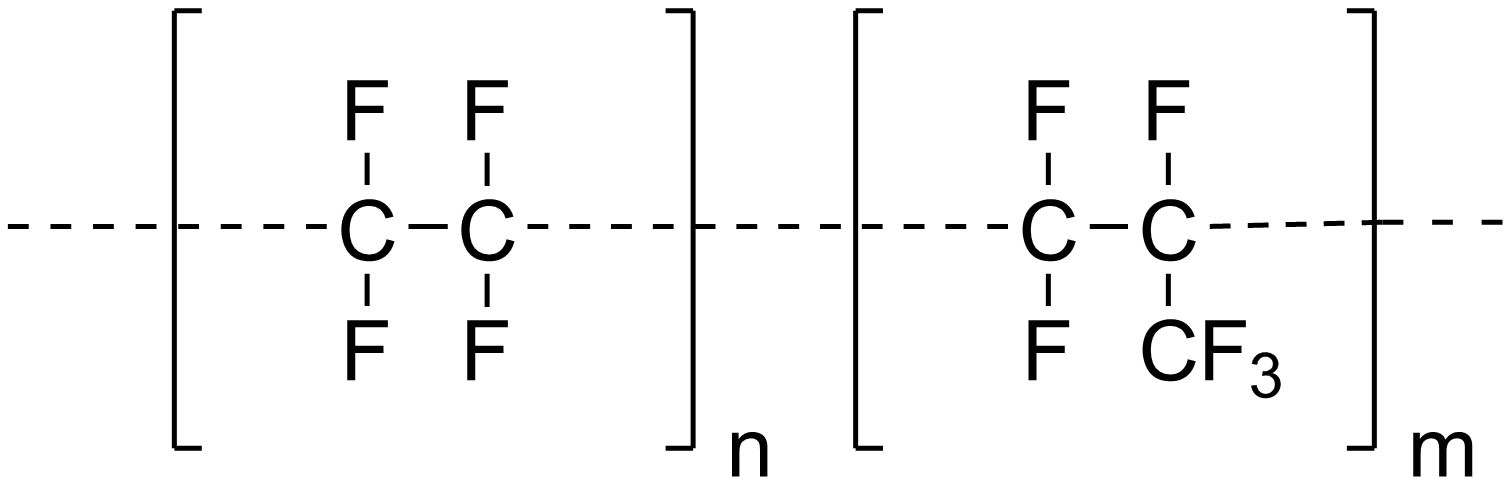

FEP: Tetrafluoroethylene/hexafluoropropylene copolymer

- Short Name

- FEP

- Name

- Tetrafluoroethylene/hexafluoropropylene copolymer

- Group

- HTRTP - High-Temperature Resistant Thermoplastics

- General Properties

- Chemical Formula

- Structural Formula

-

Properties

- Glass Transition Temperature

- - °C

- Melting Temperature

- 253 to 282 °C

- Melting Enthalpy

- - J/g

- Decomposition Temperature

- 510 to 600 °C

- Young's Modulus

- 350 MPa

- Coefficient of Linear Thermal Expansion

- 80 *10¯6/K

- Specific Heat Capacity

- 1.12 J/(g*K)

- Thermal Conductivity

- 0.25 W/(m*K)

- Density

- 2.12 to 2.17 g/cm³

- Morphology

- Semi-crystalline thermoplastic

- General properties

- Good chemical resistance. High impact strength. Smooth surface

- Processing

- Injection molding, extrusion

- Applications

- Heating cables, heating tapes. Electronics (e.g., wires, cables on the communication sector). Chemical industry (lining for valves, tubes, container). Solar cells (layer films)

Internet Links

NETZSCH Measurements

- Instrument

- DSC 204 F1 Phoenix®

- Sample Mass

- 11.12 mg

- Isothermal Phase

- 5 min

- Heating/Colling Rates

- 10 K/min

- Crucible

- Al, pierced

- Atmosphere

- N2 (50 ml/min)

Evaluation

The present FEP sample shows an endothermal melting effect at 266°C (peak temperature, 2nd heating, green) in the temperature range between 0°C and 310°C with a melting enthalpy of 24 J/g.

The shift of the peak temperature of more than 2 K to lower values in the 2nd heating (266°C compared to 268°C in the 1st heating, blue) can be explained by a better contact between the sample and crucible bottom after the first melting. The melting peak in the 1st heating (blue) is a bit slimmer compared to the 2nd heating; this indicates a narrower distribution of crystallites.

The shift of the peak temperature of more than 2 K to lower values in the 2nd heating (266°C compared to 268°C in the 1st heating, blue) can be explained by a better contact between the sample and crucible bottom after the first melting. The melting peak in the 1st heating (blue) is a bit slimmer compared to the 2nd heating; this indicates a narrower distribution of crystallites.