PA6/6T: Polyamide 6/6T

- Short Name

- PA6/6T

- Name

- Polyamide 6/6T

- Group

- HTRTP - High-Temperature Resistant Thermoplastics

- General Properties

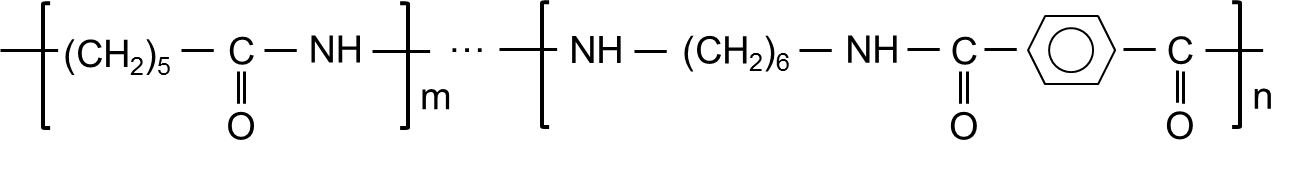

- Chemical Formula

- Structural Formula

-

Properties

- Glass Transition Temperature

- 60 to 100 °C

- Melting Temperature

- 250 to 300 °C

- Melting Enthalpy

- - J/g

- Decomposition Temperature

- 460 to 480 °C

- Young's Modulus

- 3500 to 3600 MPa

- Coefficient of Linear Thermal Expansion

- 70 *10¯6/K

- Specific Heat Capacity

- - J/(g*K)

- Thermal Conductivity

- - W/(m*K)

- Density

- 1.18 g/cm³

- Morphology

- Semi-crystalline thermoplastic

- General properties

- High mechanical stability. High chemical resistance. High toughness in the cold. Higher temperature resistance than PA6 or PA6.6

- Processing

- Injection molding

- Applications

- Electrical engineering/electronics (gear wheels, plug connectors…). Axes. Fishing equipment

Internet Links

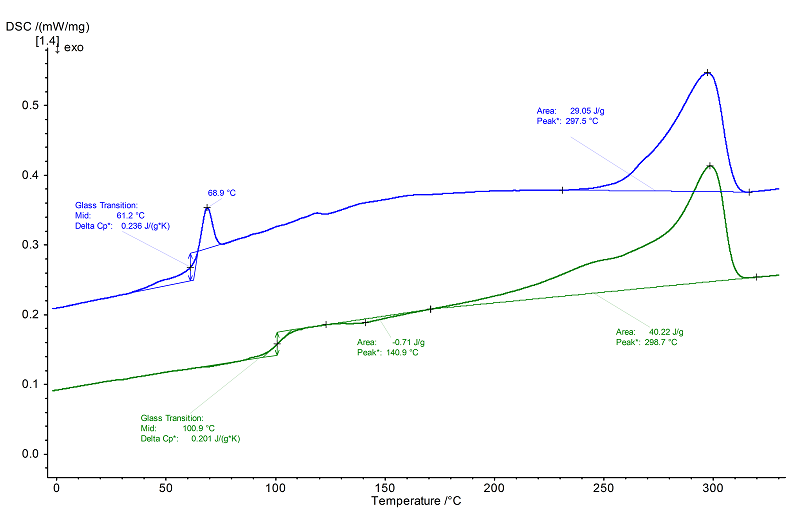

NETZSCH Measurements

- Instrument

- DSC 204 F1 Phoenix®

- Sample Mass

- 12.29 mg

- Isothermal Phase

- 5 min

- Heating/Colling Rates

- 10 K/min

- Crucible

- Al, pierced

- Atmosphere

- N2 (50 ml/min)

Evaluation

The large relaxation peak overlapping the glass transition (midpoint: 61°C) in the 1st heating (blue) indicates that this polymer sample had been tempered at 40/50°C or had been stored in that temperature range for a long period of time.

Due to the elimination of water (broad peak from approx. 90°C to 180°C) during the 1st heating, the glass transition shifted to 101°C (midpoint) in the 2nd heating (green).

In the 2nd heating (green), the sample melting began after a small exothermal post-crystallization (peak: 141°C) following the glass transition; the temperature of the main peak was 299°C. The corresponding melting enthalpy amounted to 40 J/g.

In the first heating, the total melting enthalpy was 29 J/g and thus a bit lower than in the 2nd heating, indicating that additional crystallization had occurred during the intervening cooling segment. Nevertheless, the melting temperature (peak temperature) of 298°C was similar to that in the 2nd heating.

Due to the elimination of water (broad peak from approx. 90°C to 180°C) during the 1st heating, the glass transition shifted to 101°C (midpoint) in the 2nd heating (green).

In the 2nd heating (green), the sample melting began after a small exothermal post-crystallization (peak: 141°C) following the glass transition; the temperature of the main peak was 299°C. The corresponding melting enthalpy amounted to 40 J/g.

In the first heating, the total melting enthalpy was 29 J/g and thus a bit lower than in the 2nd heating, indicating that additional crystallization had occurred during the intervening cooling segment. Nevertheless, the melting temperature (peak temperature) of 298°C was similar to that in the 2nd heating.