PEEK: Polyetheretherketone

- Short Name

- PEEK

- Name

- Polyetheretherketone

- Group

- HTRTP - High-Temperature Resistant Thermoplastics

- General Properties

- Chemical Formula

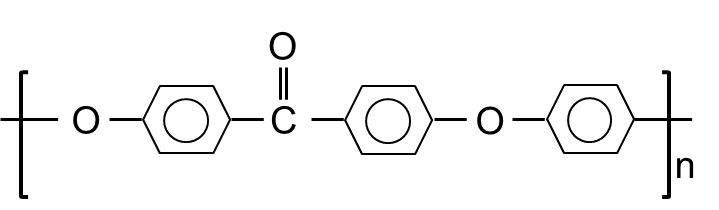

- Structural Formula

-

Properties

- Glass Transition Temperature

- 145 to 155 °C

- Melting Temperature

- 335 to 345 °C

- Melting Enthalpy

- 130 J/g

- Decomposition Temperature

- 600 to 620 °C

- Young's Modulus

- 3700 MPa

- Coefficient of Linear Thermal Expansion

- 50 to 70 *10¯6/K

- Specific Heat Capacity

- - J/(g*K)

- Thermal Conductivity

- 0.25 W/(m*K)

- Density

- 1.32 (semi-cr), 1.27 (am) g/cm³

- Morphology

- Usually semi-crystalline thermoplastics, but as a thin film generally amorphous

- General properties

- Good mechanical properties. High stability and stiffness. High temperature resistance. Good chemical and radiation resistance. Good hydrolysis resistance. Good sliding properties. Good electrical insulation properties

- Processing

- Injection molding, extrusion, machining

- Applications

- Instrument and apparatus engineering (plain bearings, gear wheels). Aerospace. Electronics. Medical engineering (surgical devices, implants). Chemical industry

Internet Links

NETZSCH Measurements

- Instrument

- DSC 204 F1 Phoenix®

- Sample Mass

- 10.39 mg

- Isothermal Phase

- 3 min/3 min/5 min

- Heating/Colling Rates

- 10 K/min

- Crucible

- Al, pierced

- Atmosphere

- N2 (40 ml/min)

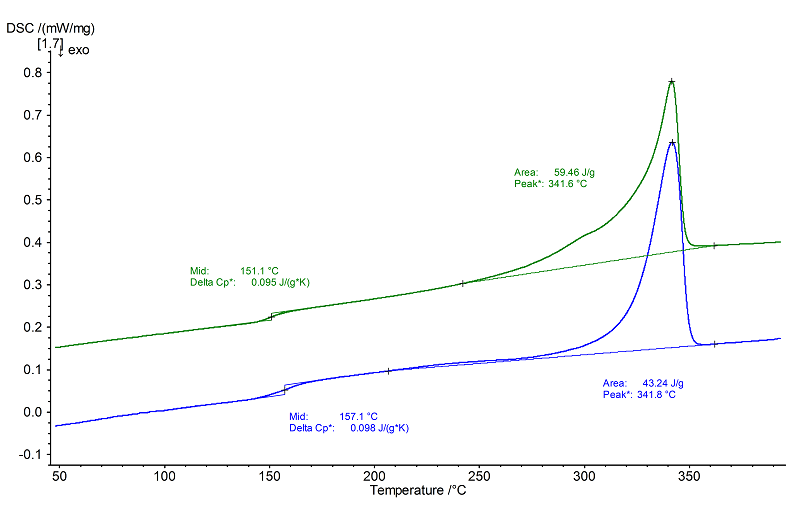

Evaluation

The peak melting temperature of the PEEK sample of approx. 342°C was essentially the same in both heatings (1st heating, blue and 2nd heating, green). The melting transition in the 2nd heating was more complex than in the 1st heating. The melting enthalpy increased from 41 J/g in the 1st heating to approx. 57 J/g in the 2nd heating, an increase of almost 40%.

The glass transition temperature, which characterizes the amorphous part, was 151°C (midpoint) in the 2nd heating (green).

The glass transition temperature, which characterizes the amorphous part, was 151°C (midpoint) in the 2nd heating (green).