PEKEKK: Polyacryletherketone- etherketoneketone

- Short Name

- PEKEKK

- Name

- Polyacryletherketone- etherketoneketone

- Group

- HTRTP - High-Temperature Resistant Thermoplastics

- General Properties

- Chemical Formula

- Structural Formula

-

Properties

- Glass Transition Temperature

- 165 to 175 °C

- Melting Temperature

- 380 to 390 °C

- Melting Enthalpy

- 60 J/g

- Decomposition Temperature

- 580 to 600 °C

- Young's Modulus

- 4300 MPa

- Coefficient of Linear Thermal Expansion

- 45 *10¯6/K

- Specific Heat Capacity

- - J/(g*K)

- Thermal Conductivity

- 0.29 W/(m*K)

- Density

- 1.3 g/cm³

- Morphology

- Semi-crystalline thermoplastic

- General properties

- Good mechanical properties. High temperature and heat resistance. Good chemical resistance. Low humidity absorption. Good electrical insulation. Good dimensional stability

- Processing

- Extrusion, injection molding

- Applications

- Mechanical engineering. Transportation and conveyor technique. Automobile industry. Chemical plant construction

Internet Links

NETZSCH Measurements

- Instrument

- DSC 204 F1 Phoenix®

- Sample Mass

- 10.69 mg

- Isothermal Phase

- 3 min/5 min

- Heating/Colling Rates

- 10 K/min

- Crucible

- Al, pierced

- Atmosphere

- N2 (40 ml/min)

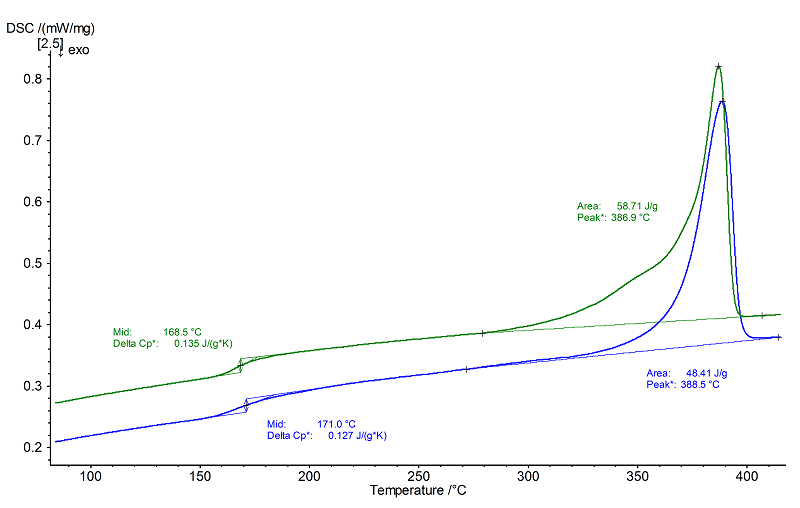

Evaluation

Since the polymer is semi-crystalline, it exhibits both a melting transition and a glass transition. The glass transition for the example occurred at approx. 168°C (2nd heating, green, midpoint), and the melting transition at 387°C (peak temperature,

2nd heating).

The melting enthalpy increased from 47 J/g in the 1st heating (blue) to approx. 59 J/g in the 2nd heating, reflecting an increase in the crystalline content of the polymer. The height of the glass transition step (Δcp), normally a measure of the

amorphous content in the sample, remained nearly constant. The small shift of the melting temperature (peak temperature) between the 1st and 2nd heatings of nearly 2 K is due to the better contact between the sample and crucible bottom after the first melting.

2nd heating).

The melting enthalpy increased from 47 J/g in the 1st heating (blue) to approx. 59 J/g in the 2nd heating, reflecting an increase in the crystalline content of the polymer. The height of the glass transition step (Δcp), normally a measure of the

amorphous content in the sample, remained nearly constant. The small shift of the melting temperature (peak temperature) between the 1st and 2nd heatings of nearly 2 K is due to the better contact between the sample and crucible bottom after the first melting.