TPU: Urethane based TPE

- Short Name

- TPU

- Name

- Urethane based TPE

- Group

- TPEM - Thermoplastic Elastomers

- General Properties

- Chemical Formula

- Structural Formula

-

Properties

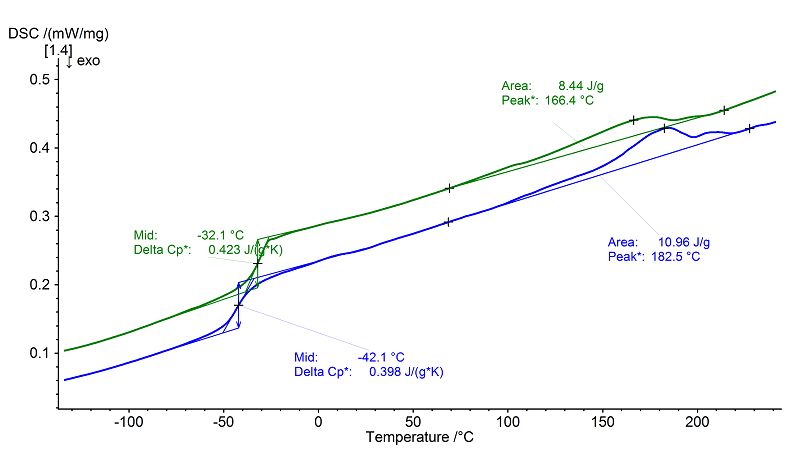

- Glass Transition Temperature

- -50 to -30 °C

- Melting Temperature

- 135 to 220 °C

- Melting Enthalpy

- 3 to 15 J/g

- Decomposition Temperature

- 390 to 415 °C

- Young's Modulus

- 20 to 400 MPa

- Coefficient of Linear Thermal Expansion

- 130 to 180 *10¯6/K

- Specific Heat Capacity

- 1.85 J/(g*K)

- Thermal Conductivity

- 0.19 W/(m*K)

- Density

- 1.10 to 1.25 g/cm³

- Morphology

- Thermoplastic elastomer, block copolymer with hard and soft segments

- General properties

- High stability and flexibility. Good oil resistance. Good weather resistance (yellowing without property loss). High resilience

- Processing

- Injection molding, extrusion, blow molding

- Applications

- Automotive industry (damping elements, clutch elements). Medical engineering (bypass). Technical rubber articles (band conveyors, tooth belts, seals). Dashboards. Shoe soles

Internet Links

NETZSCH Measurements

- Instrument

- DSC 204 F1 Phoenix®

- Sample Mass

- 11.82 mg

- Isothermal Phase

- 5 min

- Heating/Colling Rates

- 10 K/min

- Crucible

- Al, pierced

- Atmosphere

- N2 (40 ml/min)

Evaluation

Presented in the above graphic is the 2nd heating of a TPU. Along with a glass transition at -32°C (Δcp 0.42 J/(g.K)), reflecting the thermal behavior of the soft segments, the DSC curve displays a broad endothermal effect (peak temperature of the main effect 167°C, heat of fusion approx. 8 J/g) that can be attributed to the melting of hard segments.