TPS: Styrene based TPE

- Short Name

- TPS

- Name

- Styrene based TPE

- Group

- TPEM - Thermoplastic Elastomers

- General Properties

- Chemical Formula

- Structural Formula

-

Properties

- Glass Transition Temperature

- -80 to -50 (butadiene), 85 to 100 (styrene) °C

- Melting Temperature

- 150 to 160 (PP) °C

- Melting Enthalpy

- 20 J/g

- Decomposition Temperature

- 440 to 455 °C

- Young's Modulus

- 10 to 200 MPa

- Coefficient of Linear Thermal Expansion

- - *10¯6/K

- Specific Heat Capacity

- - J/(g*K)

- Thermal Conductivity

- - W/(m*K)

- Density

- 0.88 to 1.30 g/cm³

- Morphology

- Thermoplastic elastomer, copolymer with hard and soft segments

- General properties

- Good hydrolysis resistance. High thermal resistance. Good aging resistance

- Processing

- Injection molding, extrusion, blow molding

- Applications

- Shoe industry (soles). Medical products. Screwdrivers, handles, electric tools (multi-component injection molding with hard and soft segments, whereas TPS represents the soft component)

Internet Links

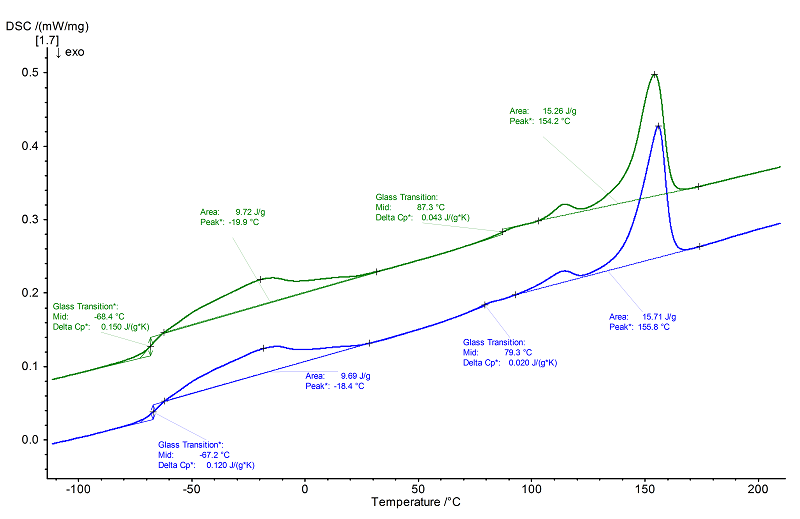

NETZSCH Measurements

- Instrument

- DSC 204 F1 Phoenix®

- Sample Mass

- 15.25 mg

- Isothermal Phase

- 8 min

- Heating/Colling Rates

- 10 K/min

- Crucible

- Al, pierced

- Atmosphere

- N2 (40 ml/min)

Evaluation

The present material is a blend from the tri-block copolymer and PP. In the 2nd heating (green), a glass transition can be seen at -68°C (midpoint), followed by a broad, endothermal effect (peak temperature -14°C), both of which are related to the butadiene component. A small glass transition for the polystyrene component can be seen at approx. 85°C (midpoint). This is followed by two endothermal effects with a total melting enthalpy of approx. 15 J/g; a smaller one at 115°C and a larger one at 154°C (peak temperature). The main peak is attributable to the melting of PP. The smaller peak at 115°C may be due to the presence of some PE. The DSC curves from the 1st and 2nd heatings are nearly identical.