BR: Butadiene rubber

- Short Name

- BR

- Name

- Butadiene rubber

- Group

- EM - Elastomers

- General Properties

- Chemical Formula

- Structural Formula

-

Properties

- Glass Transition Temperature

- -106 tp -95 (1.4 cis), -107 to -83 (1,4 trans), -15 (1,2) °C

- Melting Temperature

- -25 to 12 (1,4 cis), 97 / 145 (1,4 trans), 126 (1,2) °C

- Melting Enthalpy

- 46/170 (1,4 cis), 70 to 140 (1,4 trans) J/g

- Decomposition Temperature

- 370 to 385 / 460 to 475 °C

- Young's Modulus

- - MPa

- Coefficient of Linear Thermal Expansion

- - *10¯6/K

- Specific Heat Capacity

- 1.76 to 1.96 J/(g*K)

- Thermal Conductivity

- 0.25 W/(m*K)

- Density

- 0.9 to 1.0 g/cm³

- Morphology

- Elastomer with hard and soft segments

- General properties

- High elasticity. High stability. High abrasion resistance

- Processing

- Extrusion, calendering, injection molding, vulcanization

- Applications

- Tire industry (blends with NR or SBR). Mechanical engineering. Technical rubber goods (e.g., band conveyors). Golf balls, shoe soles

Internet Links

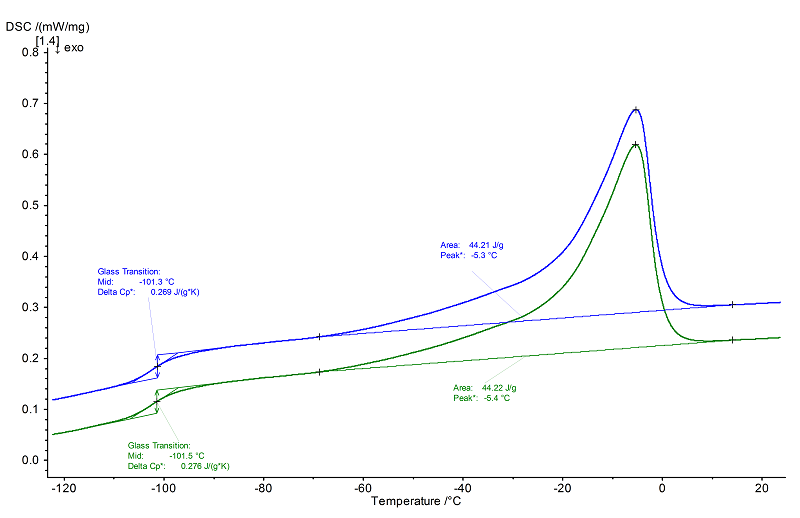

NETZSCH Measurements

- Instrument

- DSC 204 F1 Phoenix®

- Sample Mass

- 12.29 mg

- Isothermal Phase

- 8 min/3 min/8 min

- Heating/Colling Rates

- 10 K/min

- Crucible

- Al, pierced

- Atmosphere

- N2 (40 ml/min)

Evaluation

Polybutadiene or butadiene rubber has both soft and hard segments. For this reason, the above graphic shows a glass transition at -101°C (midpoint) in both heatings with a step height (Δcp) of approx. 0.27 J/(g.K) from the soft segments and a melting endotherm with a peak temperature of -5°C from the hard segments.

Based on literature data from the previous page (49 or 152), it can be concluded that the sample is mainly a 1,4 cis type.

Based on literature data from the previous page (49 or 152), it can be concluded that the sample is mainly a 1,4 cis type.