EPDM: Ethylene-propylene-diene rubber

- Short Name

- EPDM

- Name

- Ethylene-propylene-diene rubber

- Group

- EM - Elastomers

- General Properties

- Chemical Formula

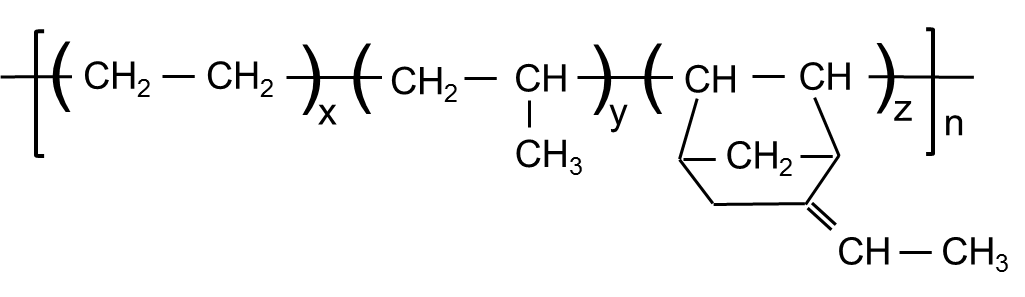

- Structural Formula

-

Properties

- Glass Transition Temperature

- -55 to -30 °C

- Melting Temperature

- -20 to 60 °C

- Melting Enthalpy

- 5 to 20 J/g

- Decomposition Temperature

- 470 to 487 °C

- Young's Modulus

- 2 to 10 MPa

- Coefficient of Linear Thermal Expansion

- 180 *10¯6/K

- Specific Heat Capacity

- 1.80 to 2.00 J/(g*K)

- Thermal Conductivity

- 0.26 W/(m*K)

- Density

- 0.86 g/cm³

- Morphology

- Rubber, sometimes with soft and hard segments

- General properties

- Very good electrical insulating properties. Very good ozone and sunlight resistance. Good aging resistance. Good resistance to heat, chemicals, hot water and water vapor

- Processing

- Cross-linking by means of sulfur (with accelerators) or peroxides

- Applications

- Seals and profiles. Cable sheathings and insulations. Cool water hoses. Components of household appliance. Construction sealing strips. Blend partners in PP-EPDM blends (TPV) to improve the impact strength of PP (application in the automobile industry as underbody or bumper material)

Internet Links

NETZSCH Measurements

- Instrument

- DSC 204 F1 Phoenix®

- Sample Mass

- 13.83 mg

- Isothermal Phase

- 7 min

- Heating/Colling Rates

- 10 K/min

- Crucible

- Al, pierced

- Atmosphere

- N2 (40 ml/min)

Evaluation

This EPDM sample is not purely amorphous since it exhibits a small melting transition at 6°C (peak temperature, 2nd heating, green) with an enthalpy of 0.8 J/g, indicating a small amount of crystalline content. The glass transition at -54°C (midpoint, both heatings) is from the amorphous content. The endothermal effect with peak temperatures of 43°C and 52°C (2nd heating, green) is probably due to the melting of additives. This appears as a single peak in the 1st heating (blue).