Q: Silicone rubber

- Short Name

- Q

- Name

- Silicone rubber

- Group

- EM - Elastomers

- General Properties

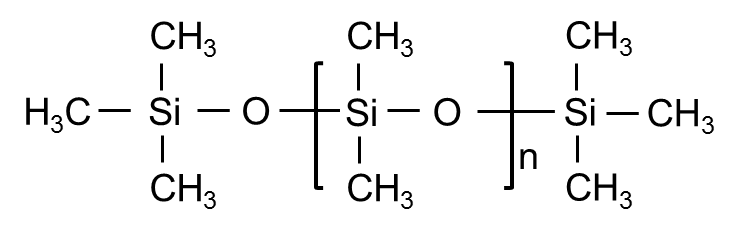

- Chemical Formula

- Structural Formula

-

Properties

- Glass Transition Temperature

- -135 to -120 °C

- Melting Temperature

- -50 to -40 °C

- Melting Enthalpy

- 35 J/g

- Decomposition Temperature

- 530 to 600 °C

- Young's Modulus

- 1 to 10 MPa

- Coefficient of Linear Thermal Expansion

- 190 to 255 *10¯6/K

- Specific Heat Capacity

- 1.3 to 1.5 J/(g*K)

- Thermal Conductivity

- 0.22 W/(m*K)

- Density

- 1.25 g/cm³

- Morphology

- Semi-crystalline rubber

- General properties

- Good aging, ozone and weather resistance. Good electrical insulating properties. Good cold flexibility

- Processing

- Cross-linking mostly by means of peroxides

- Applications

- Electrical industry (e.g., electric cable insulation). Aircraft industry (e.g., seals for window and cabin doors in planes). Accessories for instrument and apparatus engineering (e.g., O-rings)

Internet Links

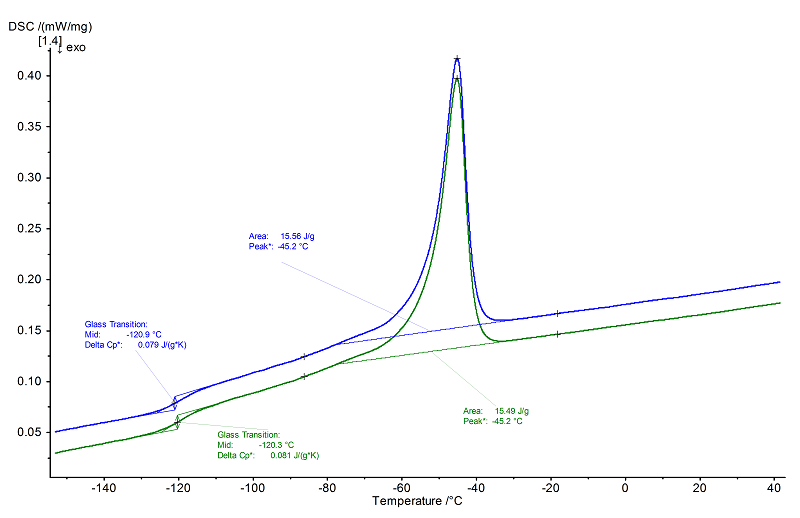

NETZSCH Measurements

- Instrument

- DSC 204 F1 Phoenix®

- Sample Mass

- 12.81 mg

- Isothermal Phase

- 8 min

- Heating/Colling Rates

- 10 K/min

- Crucible

- Al, pierced

- Atmosphere

- N2 (40 ml/min)

Evaluation

The amorphous portion of silicone rubber (Q) exhibits a very low glass transition temperature of -120°C (midpoint, 2nd heating, green). The crystalline portion exhibits a sharp melting transition with a peak temperature of -45°C (both heatings).

The detected glass transition with step heights (Δcp) of 0.08 J/(g.K), even in the 2nd heating after a controlled cooling at 10 K/min, indicates a relatively high amorphous content. Highly crystalline silicone rubbers often must be quenched (cooled very quickly) in order to make the glass transition step visible.

Due to the very low glass transition (-120°C), it is recommended to select a start temperature that is approx. 45°C to 50°C below the glass transition temperature, i.e., in this case at -165°C.

The detected glass transition with step heights (Δcp) of 0.08 J/(g.K), even in the 2nd heating after a controlled cooling at 10 K/min, indicates a relatively high amorphous content. Highly crystalline silicone rubbers often must be quenched (cooled very quickly) in order to make the glass transition step visible.

Due to the very low glass transition (-120°C), it is recommended to select a start temperature that is approx. 45°C to 50°C below the glass transition temperature, i.e., in this case at -165°C.