PE-LD: Polyethylene low density

- Short Name

- PE-LD

- Name

- Polyethylene low density

- Group

- CTP - Commodity Thermoplastics

- General Properties

- Chemical Formula

- Structural Formula

-

Properties

- Glass Transition Temperature

- -130 to - 100/-30 to -10 °C

- Melting Temperature

- 100 to 115 °C

- Melting Enthalpy

- - J/g

- Decomposition Temperature

- 487 to 498 °C

- Young's Modulus

- 200 to 400 MPa

- Coefficient of Linear Thermal Expansion

- 400 *10¯6/K

- Specific Heat Capacity

- 1.8 to 3.4 J/(g*K)

- Thermal Conductivity

- 0.3 to 0.34 W/(m*K)

- Density

- 0.91 to 0.93 g/cm³

- Morphology

- Semi-crystalline thermoplastic

- General properties

- Tough and elastic, good electric insulation, minimal moisture absorption, approved for food contact.

- Processing

- Extrusion (films, profiles), injection moulding, blow moulding, extrusion-coating.

- Applications

- Films(for a variety of applications), packaging (e.g. containers, plastic bags).

Internet Links

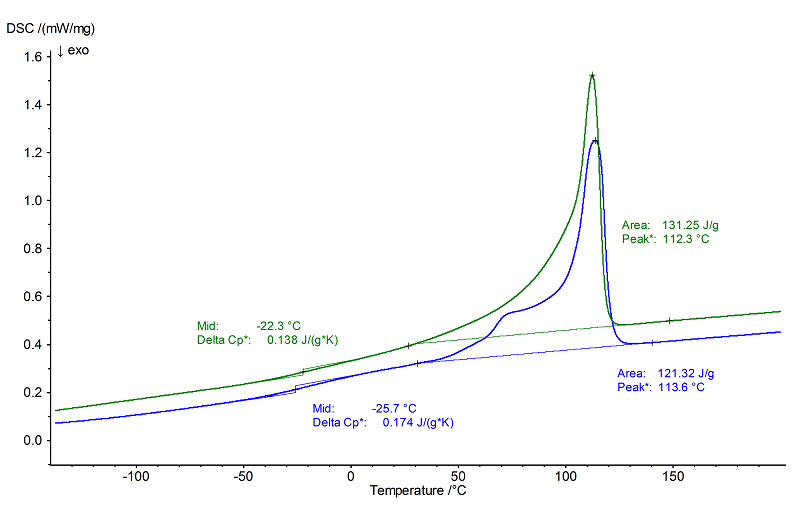

NETZSCH Measurements

- Instrument

- DSC 204 F1 Phoenix®

- Sample Mass

- 12.11 mg

- Isothermal Phase

- 20 min/2 min/20 min

- Heating/Colling Rates

- 10 K/min

- Crucible

- Al, pierced

- Atmosphere

- N2 (40 ml/min)

Evaluation

A characteristic feature of this polymer is that the melting transition – as in the present case – can start very early (here at approx. 40°C). The peak temperatures of the endothermal melting effects are at 112/113°C (1st heating, blue and 2nd heating, green) and are therefore relatively high for PE-LD. The shoulder in the melting effect in the 1st heating (blue) is absent in the 2nd heating (green). It can be concluded from this observation that stresses in the material (thermomechanical history) were eliminated during the 1st heating.

The glass transition of polyethylene is generally small (small Δcp, i.e., changes in the specific heat level prior to and after the effect) and therefore sometimes hard to detect by DSC.

The glass transition of polyethylene is generally small (small Δcp, i.e., changes in the specific heat level prior to and after the effect) and therefore sometimes hard to detect by DSC.