SBR: Styrene-butadiene rubber

- Short Name

- SBR

- Name

- Styrene-butadiene rubber

- Group

- EM - Elastomers

- General Properties

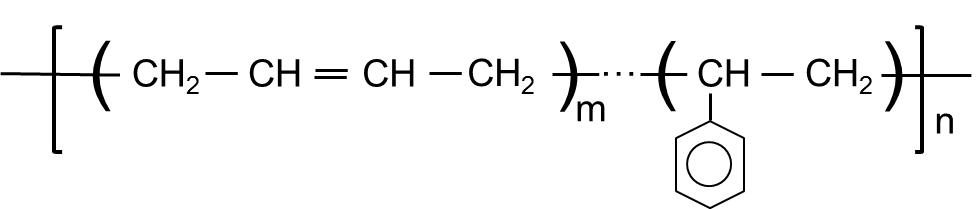

- Chemical Formula

- Structural Formula

-

Properties

- Glass Transition Temperature

- -55 to -35 °C

- Melting Temperature

- (-20) °C

- Melting Enthalpy

- (170 (cis)) J/g

- Decomposition Temperature

- 435 to 470 °C

- Young's Modulus

- 2 to 10 MPa

- Coefficient of Linear Thermal Expansion

- 180 *10¯6/K

- Specific Heat Capacity

- 1.88 to 2.00 J/(g*K)

- Thermal Conductivity

- 0.20 to 0.25 W/(m*K)

- Density

- 0.94 g/cm³

- Morphology

- Rubber with hard and soft segments

- General properties

- Good aging and abrasion resistance

- Processing

- Cross-linking by means of sulfur accelerating systems or peroxides

- Applications

- Tire industry (cap of tires). Technical rubber goods (conveyor bands, seals). Mechanical engineering. Household articles (e.g., shoe soles)

Internet Links

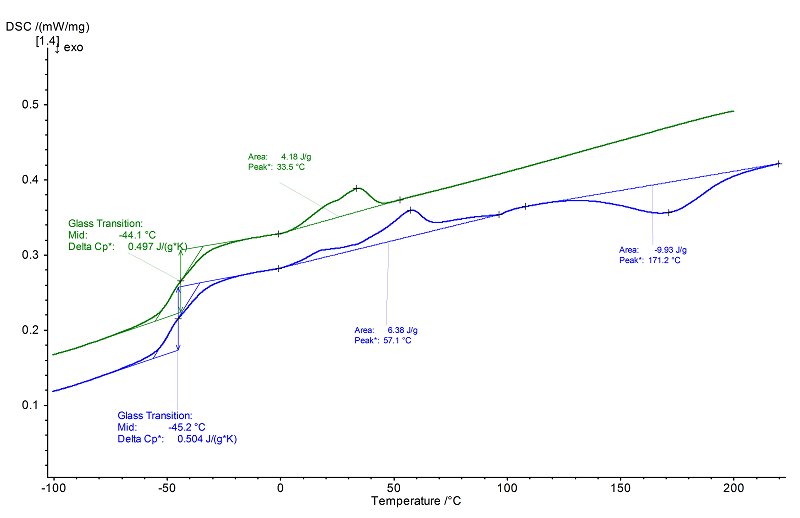

NETZSCH Measurements

- Instrument

- DSC 204 F1 Phoenix®

- Sample Mass

- 13.10 mg

- Isothermal Phase

- 8 min

- Heating/Colling Rates

- 10 K/min

- Crucible

- Al, pierced

- Atmosphere

- N2 (40 ml/min)

Evaluation

In the DSC curve from the 1st heating (blue), SBR shows a glass transition at -45°C (midpoint), a broad, complex melting transition (with peak temperatures at 19°C and 58°C and a melting enthalpy of approx. 6 J/g in the 1st heating), caused by the

melting of additives and an exothermal effect (peak temperature: 168°C, enthalpy: approx. 10 J/g) that can be attributed to post-vulcanization. This exothermal effect is absent in the 2nd heating (green) after controlled cooling, indicating that vulcanization was completed in the 1st heating. As a result, the Tg in the 2nd heating is shifted to a slightly higher temperature (midpoint of -44°C compared to -45°C in the 1st heating). The step height (Δcp) of approx. 0.5 J/(g·K) remained almost

unchanged. This small effect of post-cross linking on temperature and height of the glass transition step is typical for elastomers.

A melting transition due to additives with peak temperatures of 23°C and 34°C and an enthalpy of approx. 4 J/g is also seen in the DSC curve of the 2nd heating.

melting of additives and an exothermal effect (peak temperature: 168°C, enthalpy: approx. 10 J/g) that can be attributed to post-vulcanization. This exothermal effect is absent in the 2nd heating (green) after controlled cooling, indicating that vulcanization was completed in the 1st heating. As a result, the Tg in the 2nd heating is shifted to a slightly higher temperature (midpoint of -44°C compared to -45°C in the 1st heating). The step height (Δcp) of approx. 0.5 J/(g·K) remained almost

unchanged. This small effect of post-cross linking on temperature and height of the glass transition step is typical for elastomers.

A melting transition due to additives with peak temperatures of 23°C and 34°C and an enthalpy of approx. 4 J/g is also seen in the DSC curve of the 2nd heating.