MF: Melamine-formaldehyde resin

- Short Name

- MF

- Name

- Melamine-formaldehyde resin

- Group

- TS - Thermosets

- General Properties

- Chemical Formula

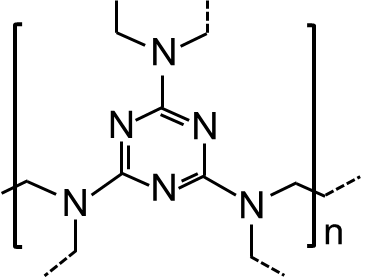

- Structural Formula

-

Properties

- Glass Transition Temperature

- 70 to 130 °C

- Melting Temperature

- - °C

- Melting Enthalpy

- - J/g

- Decomposition Temperature

- 340 to 400 °C

- Young's Modulus

- 6000 to 10000 MPa

- Coefficient of Linear Thermal Expansion

- 40 to 60 *10¯6/K

- Specific Heat Capacity

- 1.2 J/(g*K)

- Thermal Conductivity

- 0.35 to 0.40 W/(m*K)

- Density

- 1.48 to 1.50 g/cm³

- Morphology

- Thermoset

- General properties

- Good chemical resistance. High gloss. High surface hardness. High abrasion resistance. Good electrical insulating properties

- Processing

- Compression, injection molding, extrusion molding

- Applications

- Furniture industry (adhesive resin for, e.g., wood bonding, face veneer …). Electrical industry. Impregnation of textiles. Matrix for fiber-reinforced composites. Camping dishes, kitchen tools

Internet Links

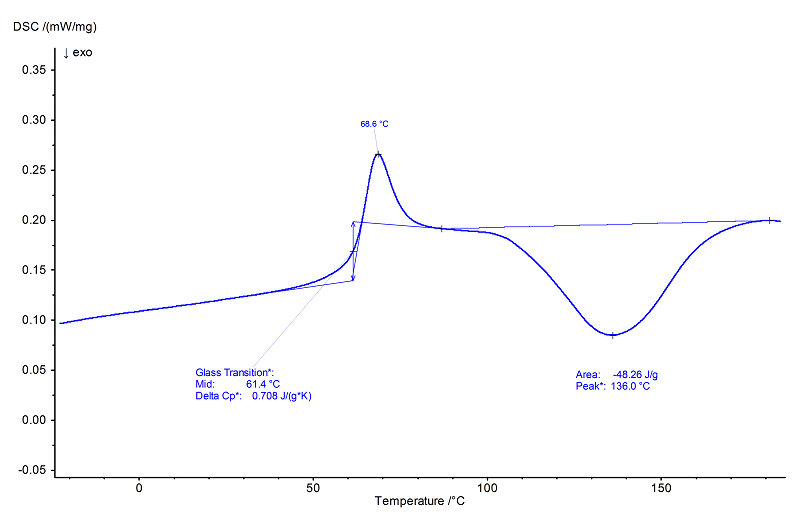

NETZSCH Measurements

- Instrument

- DSC 204 F1 Phoenix®

- Sample Mass

- 24.79 mg

- Isothermal Phase

- 8 min

- Heating/Colling Rates

- 5 K/min

- Crucible

- High-pressure crucibles of steel, closed

- Atmosphere

- N2 (40 ml/min)

Evaluation

The above plot shows a DSC curve from a single heating of a melamine formaldehyde resin (MF).

The glass transition at approx. 61°C (midpoint) is overlapped by a large endothermal enthalpy relaxation peak (peak temperature 69°C) and is immediately followed by an exothermal curing with a peak temperature of approx. 136°C and a reaction

enthalpy of 48 J/g.

A temperature-modulated DSC (TM-DSC) measurement (not presented here) would be able to separate the reversing glass transition from the non-reversing endothermal relaxation and the exothermal reaction peaks.

The glass transition at approx. 61°C (midpoint) is overlapped by a large endothermal enthalpy relaxation peak (peak temperature 69°C) and is immediately followed by an exothermal curing with a peak temperature of approx. 136°C and a reaction

enthalpy of 48 J/g.

A temperature-modulated DSC (TM-DSC) measurement (not presented here) would be able to separate the reversing glass transition from the non-reversing endothermal relaxation and the exothermal reaction peaks.