PF: Phenol-formaldehyde resin

- Short Name

- PF

- Name

- Phenol-formaldehyde resin

- Group

- TS - Thermosets

- General Properties

- Chemical Formula

- Structural Formula

-

Properties

- Glass Transition Temperature

- 70 to 120 °C

- Melting Temperature

- - °C

- Melting Enthalpy

- - J/g

- Decomposition Temperature

- 450 to 555 °C

- Young's Modulus

- 5600 to 12000 MPa

- Coefficient of Linear Thermal Expansion

- 15 to 50 *10¯6/K

- Specific Heat Capacity

- 1.0 to 1.3 J/(g*K)

- Thermal Conductivity

- 0.35 to 0.70 W/(m*K)

- Density

- 1.40 to 1.80 g/cm³

- Morphology

- Thermoset

- General properties

- Very hard and stiff. Good chemical resistance. Low inflammability

- Processing

- Compression, injection molding, extrusion molding, transfer molding, foaming

- Applications

- Electrical industry (e.g., for circuit boards, plugs). Building industry (weather-resistant glue, for production of insulating materials). Vehicle construction. Matrix for fiber-reinforced composites

Internet Links

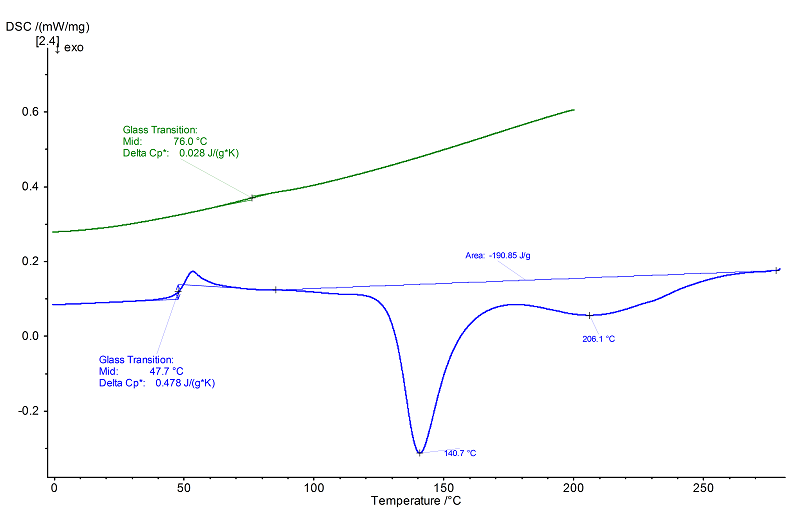

NETZSCH Measurements

- Instrument

- DSC 204 F1 Phoenix®

- Sample Mass

- 26.26 mg

- Isothermal Phase

- 10 min

- Heating/Colling Rates

- 5 K/min/10 K/min cooling/20 K/min

- Crucible

- High-pressure steel crucibles, closed

- Atmosphere

- N2 (40 ml/min)

Evaluation

The 1st heating (blue ) shows a glass transition at approx. 48°C (midpoint) with an overlapping enthalpy relaxation, followed by a multi-step exothermal curing effect with peak temperatures of 141°C and 206°C and a total enthalpy of 191 J/g. In the

following 2nd heating (green), the glass transition shifted to approx. 72°C (midpoint) as a result of the extensive curing in the previous heating step.

following 2nd heating (green), the glass transition shifted to approx. 72°C (midpoint) as a result of the extensive curing in the previous heating step.