PUR: Polyurethane

- Short Name

- PUR

- Name

- Polyurethane

- Group

- TS - Thermosets

- General Properties

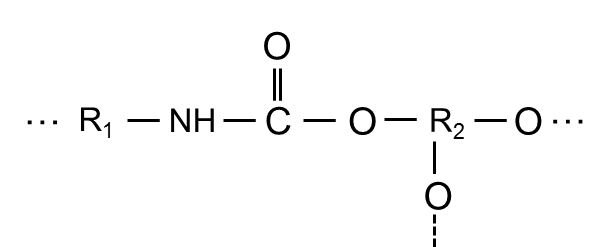

- Chemical Formula

- Structural Formula

-

Properties

- Glass Transition Temperature

- 10 to 180 °C

- Melting Temperature

- - °C

- Melting Enthalpy

- - J/g

- Decomposition Temperature

- 240 to 350 °C

- Young's Modulus

- - MPa

- Coefficient of Linear Thermal Expansion

- 130 to 200 *10¯6/K

- Specific Heat Capacity

- 1.70 to 2.10 J/(g*K)

- Thermal Conductivity

- < 0.19 W/(m*K)

- Density

- 1.10 to 1.70 g/cm³

- Morphology

- Thermoset

- General properties

- Depending on the composition – the stiffness range expands from soft rubbers to technical plastics. Good abrasion resistance

- Processing

- Injection molding, foaming, coating

- Applications

- Automotive industry. Furniture industry. Building industry. Sports and leisure. Shoe industry (soles). Polyurethane paints and coatings. Casting compounds. Matrix for composites

Internet Links

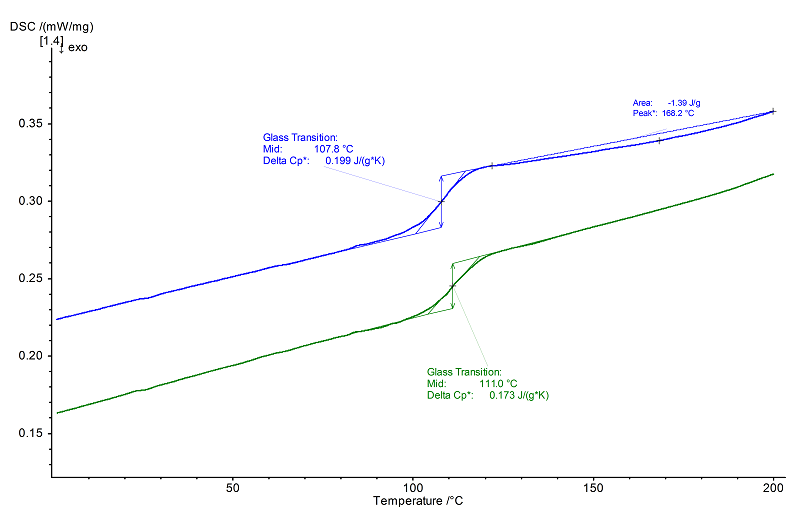

NETZSCH Measurements

- Instrument

- DSC 204 F1 Phoenix®

- Sample Mass

- 18.95 mg

- Isothermal Phase

- 5 min

- Heating/Colling Rates

- 10 K/min

- Crucible

- Al, pierced

- Atmosphere

- N2 (40 ml/min)

Evaluation

In the 1st heating, the glass transition at 107°C (midpoint) was followed by a broad, shallow, exothermal post-curing effect between approx. 120°C and 200°C (peak temperature 167°C). Due to the post-curing, the glass transition in the 2nd heating

(after controlled cooling) was approx. 4 K (midpoint temperature 111°C) higher.

The position of the glass transition temperature is directly related to the degree of curing.

The more extensive the post-curing, the more the glass transition shifts to higher temperatures.

(after controlled cooling) was approx. 4 K (midpoint temperature 111°C) higher.

The position of the glass transition temperature is directly related to the degree of curing.

The more extensive the post-curing, the more the glass transition shifts to higher temperatures.