UF: Urea-formaldehyde resin

- Short Name

- UF

- Name

- Urea-formaldehyde resin

- Group

- TS - Thermosets

- General Properties

- Chemical Formula

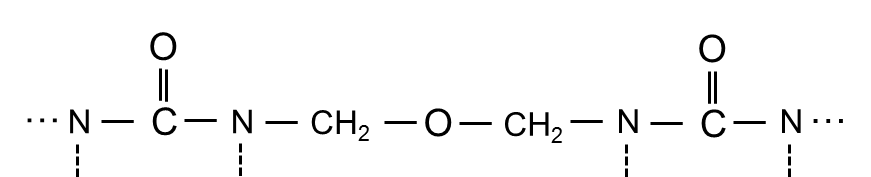

- Structural Formula

-

Properties

- Glass Transition Temperature

- 60 to 110 °C

- Melting Temperature

- - °C

- Melting Enthalpy

- - J/g

- Decomposition Temperature

- 260 to 355 °C

- Young's Modulus

- 7000 to 10500 MPa

- Coefficient of Linear Thermal Expansion

- 40 to 60 *10¯6/K

- Specific Heat Capacity

- 1.2 to 1.3 J/(g*K)

- Thermal Conductivity

- 0.35 to 0.40 W/(m*K)

- Density

- 1.5 g/cm³

- Morphology

- Thermoset

- General properties

- High strength. High scratch resistance. Very good electrical insulating properties. Light resistant

- Processing

- Compression, injection molding, transfer molding

- Applications

- Building industry (binder for plywood). Electrical industry (e.g., plugs, light switches). Sanitary area (e.g., toilet seats). Caps for cosmetics

Internet Links

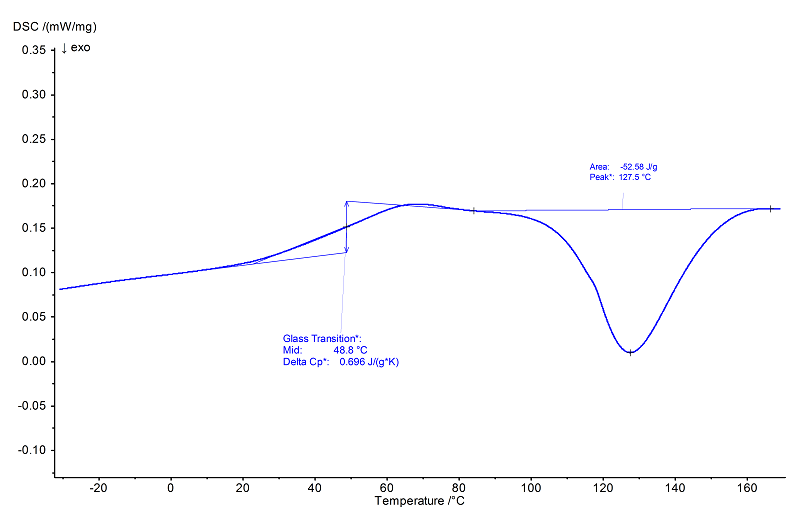

NETZSCH Measurements

- Instrument

- DSC 204 F1 Phoenix®

- Sample Mass

- 24.04 mg

- Isothermal Phase

- 8 min

- Heating/Colling Rates

- 5 K/min heating/10 K/min cooling

- Crucible

- High-pressure steel crucibles, closed

- Atmosphere

- N2 (40 ml/min)

Evaluation

In the 1st heating (blue), a glass transition occurred at 45°C (midpoint), overlapped by a small endothermal relaxation effect which is followed by a broad exothermal reaction peak due to the curing reaction (peak temperature 128°C, reaction enthalpy 53 J/g). After controlled cooling, only a glass transition with a midpoint temperature of 104°C and a step height (Δcp) of 0.14 J/(g·K) can be seen in the 2nd heating (green). This Tg is also overlapped by a relaxation effect.

By means of TM-DSC (temperature-modulated DSC), it is possible to separate the glass transition from the relaxation endotherm and the curing exotherm.

By means of TM-DSC (temperature-modulated DSC), it is possible to separate the glass transition from the relaxation endotherm and the curing exotherm.