PE-LLD: Polyethylene linear low density

- Short Name

- PE-LLD

- Name

- Polyethylene linear low density

- Group

- CTP - Commodity Thermoplastics

- General Properties

- Chemical Formula

- Structural Formula

-

Properties

- Glass Transition Temperature

- -130 to -100 / -70 to -25 °C

- Melting Temperature

- 122 to 127 °C

- Melting Enthalpy

- - J/g

- Decomposition Temperature

- 475 to 485 °C

- Young's Modulus

- 250 to 700 MPa

- Coefficient of Linear Thermal Expansion

- 200 *10¯6/K

- Specific Heat Capacity

- - J/(g*K)

- Thermal Conductivity

- - W/(m*K)

- Density

- 0.91 to 0.94 g/cm³

- Morphology

- Semi-crystalline thermoplastic

- General properties

- Balanced relationship of toughness and stiffness, good chemical resistance, good electrical insulating properties.

- Processing

- Extrusion (films, profiles), injection moulding, blow moulding, extrusion-coating.

- Applications

- Films (allows for lower film thickness than PE-LD), mainly in household and agriculture, packaging (e.g. containers and plastic bags), toys.

Internet Links

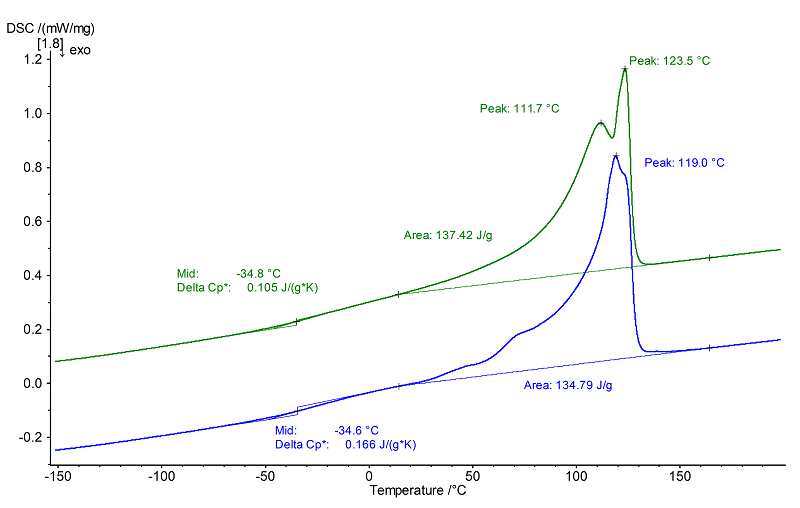

NETZSCH Measurements

- Instrument

- DSC 204 F1 Phoenix®

- Sample Mass

- 11.95 mg

- Isothermal Phase

- 20 min/2 min/20 min

- Heating/Colling Rates

- 10 K/min

- Crucible

- Al, pierced

- Atmosphere

- N2 (40 ml/min)

Evaluation

The 1st heating (blue) exhibits a highly structured melting endotherm with a main peak (at 119°C) and several upstream and downstream shoulders, reflecting the presence of stresses (thermomechanical history).

In the 2nd heating (green), two peaks at approx. 112°C and 124°C remained. Due to side chain branching, different melting phases are formed which melt one after the other. The corresponding melting enthalpy in the 2nd heating amounts to approx. 137 J/g. Since PE-LLD is a semi-crystalline thermoplastic, the glass transition observed at -35°C (for both heatings) can be related to the amorphous component of the polymer.

A second possible glass transition at approx. -100°C to -130°C, which could be due to the different crystallite structures, is not viewable in the plots shown.

In the 2nd heating (green), two peaks at approx. 112°C and 124°C remained. Due to side chain branching, different melting phases are formed which melt one after the other. The corresponding melting enthalpy in the 2nd heating amounts to approx. 137 J/g. Since PE-LLD is a semi-crystalline thermoplastic, the glass transition observed at -35°C (for both heatings) can be related to the amorphous component of the polymer.

A second possible glass transition at approx. -100°C to -130°C, which could be due to the different crystallite structures, is not viewable in the plots shown.