PE-UHMW: Polyethylene ultra high molecular weight

- Short Name

- PE-UHMW

- Name

- Polyethylene ultra high molecular weight

- Group

- CTP - Commodity Thermoplastics

- General Properties

- Chemical Formula

- Structural Formula

-

Properties

- Glass Transition Temperature

- -130 to -100 °C

- Melting Temperature

- 130 to 145 °C

- Melting Enthalpy

- - J/g

- Decomposition Temperature

- 480 to 490 °C

- Young's Modulus

- 570 to 790 MPa

- Coefficient of Linear Thermal Expansion

- 200 *10¯6/K

- Specific Heat Capacity

- 1.84 J/(g*K)

- Thermal Conductivity

- 0.41 to 0.51 W/(m*K)

- Density

- 0.93 to 0.94 g/cm³

- Morphology

- Semi-crystalline thermoplastic

- General properties

- Good sliding characteristics, high abrasion resistance, very low water absorption, high chemical resistance, very high impact strength.

- Processing

- Compression moulding, extrusion.

- Applications

- Fibres (light, high-stiff, e.g. reinforcement, sport accessories), medical engineering (implants), cables.

Internet Links

NETZSCH Measurements

- Instrument

- DSC 204 F1 Phoenix®

- Sample Mass

- 12.52 mg

- Isothermal Phase

- 20 min/2 min/20 min

- Heating/Colling Rates

- 10 K/min

- Crucible

- Al, pierced

- Atmosphere

- N2 (40 ml/min)

Evaluation

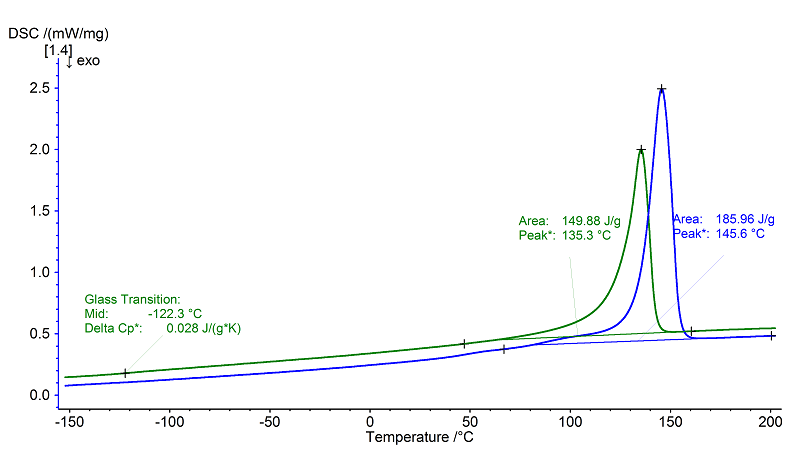

Like all polyethylenes, PE-UHMW is a semi-crystalline thermoplastic. The example shown exhibited a glass transition at -122°C (with a very small change in specific heat of 0.03 J/(g·K)) only in the 2nd heating (green curve).

The present sample was not granular. Rather, it was but a fine powder. Due to sintering of the powder during the 1st heating (blue), the melting effect (peak temperature) shifted by about 10 K to lower temperatures (from 146°C to 135°C) in the 2nd heating (green). The melting enthalpy decreased by approx. 19% from 185 J/g to approx. 150 J/g in the 2nd heating.

The present sample was not granular. Rather, it was but a fine powder. Due to sintering of the powder during the 1st heating (blue), the melting effect (peak temperature) shifted by about 10 K to lower temperatures (from 146°C to 135°C) in the 2nd heating (green). The melting enthalpy decreased by approx. 19% from 185 J/g to approx. 150 J/g in the 2nd heating.